Defextiles: Tulle from the 3D printer

Researchers at the MIT Media Lab in Massachusetts have succeeded in printing a tulle-like textile for the first time. The material, called Defextiles, is the result of a common error in 3D printing.

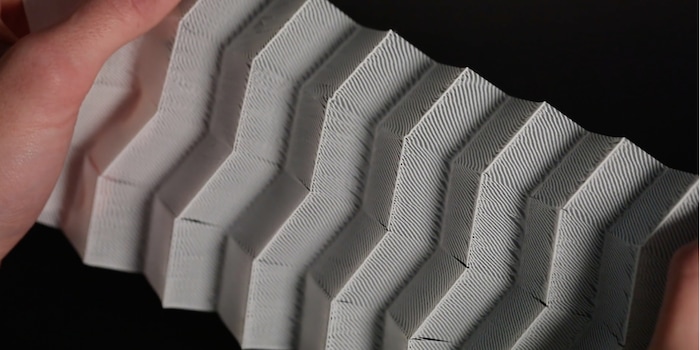

Innovation is a top priority at the MIT Media Lab in Massachusetts. Among other things, scientists at the creative centre are working on products from the 3D printer. One of these is Defextiles, a new type of textile. It was developed by PhD student Jack Forman. It is based on a typical error in 3D printing: under-extrusion. This is the term used to describe a situation in which the printer's nozzle does not spit out enough material. Due to this lack of material, the printed layers do not stick together sufficiently. This creates voids between the individual layers.

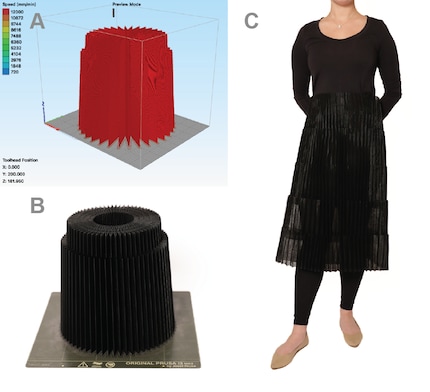

For his innovation, the researcher utilises the cyclical "gap defects" of a sub-extrusion. By constantly controlling these during printing and maintaining all the necessary printing parameters, he creates a tulle-like material that looks like a woven fabric and can be moulded as desired. In addition to skirts and lace fabrics, Jack has already used it to make shuttlecocks and interactive lampshades:

The 3D textile, which is around 0.4 millimetres thick, is not only elastic but can also be printed quickly. What's more, this process is relatively inexpensive; a conventional PLA printer is sufficient for printing and no expensive software is required. This makes Defextiles affordable and accessible to the masses.

The researcher uses polylactic acid (PLA) as the base material for the 3D tulle. This is a biodegradable plastic obtained from corn starch or sugar cane. However, because PLA can only be broken down under industrial composting conditions, the bio-based plastic is not sustainable.

To make his innovation "greener", Forman wants to use biodegradable textiles made from coffee grounds or algae in the future. In this way, the scientist is making a small but important article in establishing sustainable fashion.

When I’m not exploring the depths of the sea as an open water diver, I enjoy plunging into the world of fashion. On the streets of Paris, Milan and New York is where I keep my eyes peeled for the latest trends. And I’ll show you how to take them from the catwalk to your everyday life.