Adidas presents 3D-printed running shoe

With the textile innovation "Futurecraft Strung", Adidas wants to change the way shoes will be designed in the future.

Shoe manufacturers are competing to see who will launch the first 3D-printed shoe. Alongside Reebok and New Balance, Adidas is also working hard on 3D-printed elements such as insoles, etc. The German sports manufacturer's latest innovation is the "Futurecraft Strung" running shoe, which is the result of a new type of textile printing process.

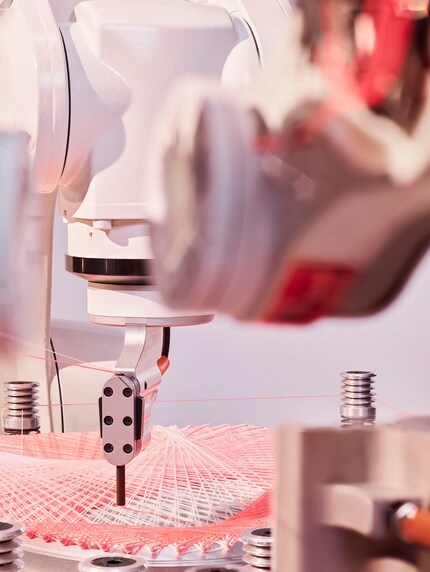

The "Strung" textile printing process is based on data, robotics and additive manufacturing (AM). To produce the running shoe, software is first used to test various structures and determine where stability and flexibility are required in the upper material. The shoe is then woven by a robotic arm.

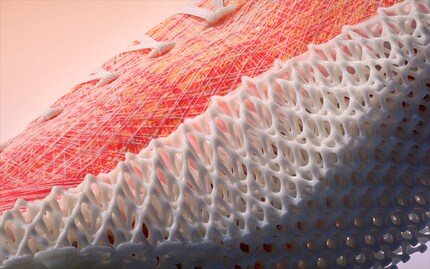

The composition and placement of each thread is determined individually based on an athlete's training data. In this way, Adidas ensures that the upper material, once woven, is modelled on the contours of the athlete's foot. While strong threads at the heels, in the midfoot area and at the toes ensure that the foot does not slip in the shoe, the soft and stretchy threads in the forefoot area provide flexibility. In this way, the Futurecraft Strung is flexible and stable without any additional components - which are normally used to reinforce conventional training shoes. At the same time, the seamless upper material is designed to be lightweight and breathable.

The name Futurecraft says it all. In addition to additive manufacturing for the upper material of the running shoe, Futurecraft technology is used for the lower part: the midsole is produced using Digital Light Synthesis (DLS) from carbon, in which a resin is cured layer by layer. The result is a disposable sole with a grid structure that ensures optimum cushioning when running.

Music of the future?

Running is just the beginning. The German sports brand wants to use Strung across all sports sooner or later, as the potential of this technology is far from exhausted. Further tests with various prototypes are already being planned in order to drive forward further development quickly. For this reason, the Futurecraft Strung is not commercially available for the time being. The official sales launch is planned for early 2022.

You can find more information here: [[video:143023]]

When I’m not exploring the depths of the sea as an open water diver, I enjoy plunging into the world of fashion. On the streets of Paris, Milan and New York is where I keep my eyes peeled for the latest trends. And I’ll show you how to take them from the catwalk to your everyday life.

From the latest iPhone to the return of 80s fashion. The editorial team will help you make sense of it all.

Show all