I capitulate after 15 hours of building time

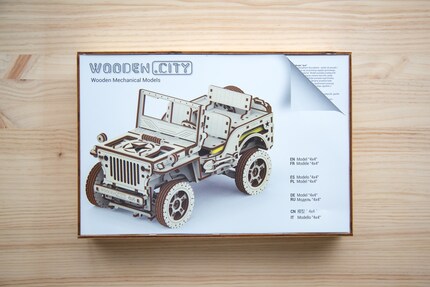

The "Allrad-Jeep" is the largest set in terms of parts from the modelling manufacturer "WoodenCity". I wanted to put my dexterity to the test by building it, but failed miserably.

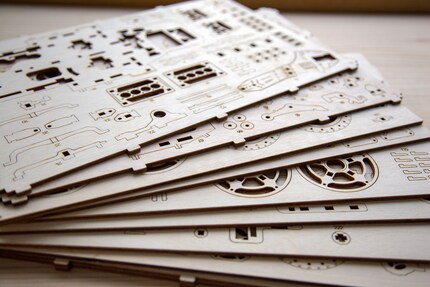

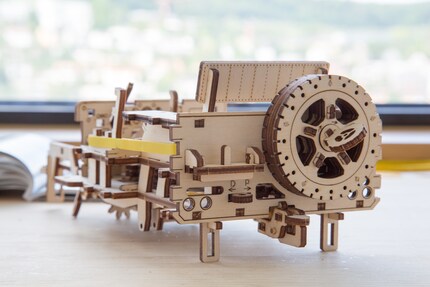

The "WoodenCity Jeep 4x4" has 569 individual parts made from birch plywood and should be built in around 12 hours according to the manufacturer. Its individual parts are pre-lasered on several wooden arches and can be cut out by hand or with a pointed tool. What sounds simple is more difficult than expected. Because they break quickly. Very quickly, in fact.

The first setback right at the start

In addition to the model kit, you will also need a cutter and a few tealights. Use the cutter to remove the protruding pieces of wood left over from cutting the individual parts out of the sheets. The wax from the tea lights is there to make the cogwheels smoother. I've got all the things I need, created a tidy working environment and mentally prepared myself for a modelling marathon. So I am ideally prepared. Let the odyssey begin.

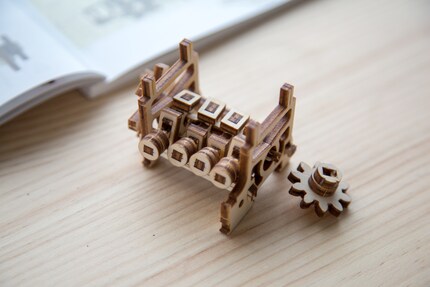

First up is the engine. In addition to the four cylinders, this also includes a radiator grille fan, a crankshaft and a frame to hold the engine in position. However, the structure is wobbly and half loose. Every now and then a part gets loose and I have to fiddle it back into place. When I then try to attach the gearwheel to the crankshaft, the first piece breaks apart. The Jeep would still be able to drive forwards and backwards later, but the cylinders would no longer be able to move due to the broken crankshaft. I start to feel disillusioned.

Inaccurate individual parts and poor quality

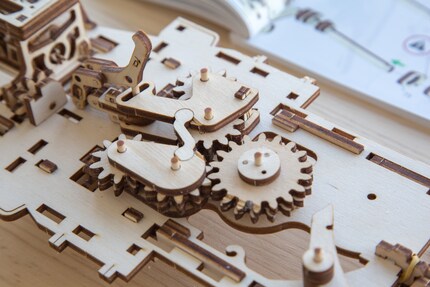

I've been working on the construction for several hours now. Every now and then a small piece of wood breaks off. Be it when cutting it out of the sheets or when assembling it. Something may crumble off here and there without causing any major consequential damage, but nothing works at all with the gearbox. The gears are inaccurately manufactured and the wood is of poor quality. With a lot of effort and a good dose of anger, I manage to get the whole thing together. Everything should actually mesh smoothly here, but the cogwheels can only be moved to a limited extent. My fingers are aching and my patience is wearing thin. I'd like to set the whole model on fire. I need a break. A long break.

It's now a week later. I've calmed down again and I'm in good spirits that I'll be able to finish building the jeep today. As I've already spent eight hours on this model and the manufacturer describes the total build time as 12 hours, I should be finished in just over four hours. That would be nice.

The next capital damage is not long in coming. I've now reached the spare wheel at the back of the car. This also conceals the wind-up mechanism for moving the Jeep. You can tension a rubber band with a spanner. This tension is then transferred to the gearbox and then to the wheels. That's the theory. But as you know, my gearbox has its difficulties and doesn't run smoothly. The first time I try to wind it up, the key also breaks off. So now nothing works at all. The thing is only good for decorative purposes.

First halfway through? Forget it!

Very annoyed, I continue building for a few more hours. I have no more motivation. What's the point? The whole thing has become useless because all the important elements are broken. I've now been working on this model for a total of 15 hours. When I read in the assembly instructions that I'm now halfway through, I'm gutted. Forget it! Not with me! I won't last that long again. I usually finish everything I've started, but this is the final straw. The chassis and wheels are no good to me anyway if the drive is fucked up.

Conclusion

On the face of it, this model is interesting. It is made of ecological wood, was manufactured in the EU, does not need to be glued and looks cool. If it weren't for the poor quality. It spoils all the fun of the model. This cheap plywood only serves as firewood. The manufacturer would have been better off using high-quality material and raising the price. Cheap is not always good. I also totally overestimated my modelling skills. Starting with the biggest and most complicated set was definitely a bad idea. I should probably have started with a simpler set, such as the doppeldecker-airplane with 63 parts. If filigree employees with their hands are exactly your thing, the wooden models from WoodenCity and Ugears might be of interest to you. I, on the other hand, am not the type and will keep my hands off such things in future.