Behind the scenes

How a software engineer fell in love with logistics

by Tiago Santos Baranita

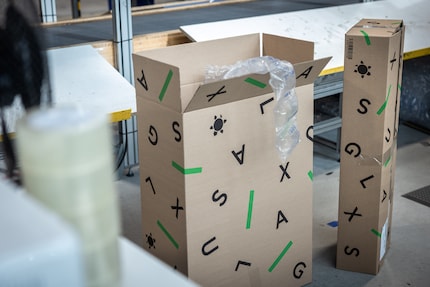

In November, Digitec Galaxus introduced new box sizes for parcels. While this might sound simple, it was actually a feat of mathematical brilliance. Supply Chain Process Engineer Aurel Gautschi, who spearheaded the initiative, gives us an insight into his work.

In November 2022, a major change took place at Digitec Galaxus’ Swiss warehouses. Overnight, we introduced nine new box sizes for parcels. The new dimensions are optimised for the Swiss product range and are designed to ensure parcels can be sent out with fewer air cushions inside. The development of the new box sizes, however, took more than just one night. Parcel-pusher-in-chief Aurel Gautschi had three solutions for optimisation on the table – two internal and one external. In this interview, Aurel reveals which approach he chose and what a Turkish takeaway shop had to do with it.

We’ve been trying to find the optimal parcel sizes for tens of thousands of products. When I hear that, I think of a problem you’d find in a school maths textbook. Only a lot more complicated. Is that an accurate comparison?

Aurel: It didn’t so much remind me of school maths as it did my ‹Data Structures and Algorithms› lectures at uni. But the stuff I learned at university was easy compared to the complexity of the box sizes.

What was so complex about the task?

The huge amount of data. From a solution space of about 250,000 carton sizes, we selected a set of 7 to 9 boxes that serve as ideal packaging for products in our range. This allows for a 21-digit number of possible combinations. Mind you, this ignores the almost infinite number of possibilities for positioning the ridges. Basically, we worked with assumptions and a ‹divide and conquer› approach to split the large problem into smaller sub-problems that we’d then solve.

You’re still in the middle of your bachelor’s degree. How did you deal with the responsibility of this project? Didn’t it ever have you breaking out in a cold sweat?

I knew enough to set out the parameters of the solution and coordinate the teams on the business side of things. But I wouldn’t have been able to implement the final solution on my own. I got some experts on board to help with that. These folks understand more about their field than I do. My job was to bring together all the different threads.

How did you go about doing that?

With such a complex project, I thought it was important for us to have several proposals for solutions. I wanted to prevent us from running off in one direction and losing sight of important aspects. Three approaches were in the running. Hakim from our Business Intelligence Team, ‹Cyclops›, submitted one of them. Another came from Raphael Renaud, our Head of Engineering. And the third proposal came from Ergon, an external software company. To prevent the three groups from influencing each other, I made a conscious decision to deal with them separately.

How did Raphael end up developing a solution himself?

That was a kebab shop idea. At lunchtime, I went to get a kebab and happened to run into Raphael at the takeaway shop. Our initial bit of small talk about an ongoing project quickly turned into an intense conversation. Surrounded by cocktail sauce, bread and onions, I told him about the box sizes for parcels. Raphael found the project so interesting that we actually started discussing the first solutions in the restaurant. Once I was back in my home office, we carried on our conversation in a virtual meeting. As I was giving Raphael the requirements on the business operations side, he was writing the first lines of code. After that, he ran everything through the computer, and 42 hours later, the first results were in.

You must know quite a bit about programming to keep up with that kind of pace.

Before I started my current degree, I studied two years of Computational Sciences and Engineering at ETH Zurich. The knowledge I gained back then helps me a lot today, especially since I really should have a certain understanding of it as a process engineer.

So, coding got its hooks into you after all.

I’ll probably never leave coding behind completely, and I don’t want to. As process engineers, we’re positioned somewhere between the software development team and the day-to-day business of logistics. In this role, we have the opportunity to solve operational issues such as box sizes with smart software. That appeals to me more than the purely technical implementation of solutions.

Why did you want to have three solutions on the table?

In the beginning, we had a rough idea of how the solution could go. That being said, it would’ve been disastrous if we’d come up with a solution based on an incorrect algorithm. So, we put the three solutions through rigorous testing in various situations. It’s only when every proposal goes in the same direction that we know we’re on the right track. And that’s exactly what happened with our three approaches. All three were very close to each other.

And why did we also test a solution that was created externally? We usually develop our software ourselves, don’t we?

Ergon has a lot of experience in the field of optimisation. To give an example, it optimised inventory levels for a customer by using machine learning. That certainly benefitted the team. Alain and Willi, who dealt with us at Ergon, are absolute experts in their field. Both have a PhD in Computer Science from ETH and presented us with the most complex solution. It’s true that we usually go for internal solutions. But it was also really rewarding to work with an external software provider for a change.

In the end, you chose Ergon’s solution. What was it that made this proposal the strongest of the bunch?

All three solutions delivered in the categories of air content, ergonomics and raw material consumption. Each of the three teams did a great job. I used a short Python script to evaluate the solutions separately according to various criteria. One example of these was calculating which sizes of box our employees could pack more quickly. Minor differences were noticeable there. Based on these criteria, Ergon’s algorithm provided better solutions, which was the deciding factor.

What was the argument for having nine different sizes?

Each team gave me three solutions – using seven, eight and nine different box sizes. I rounded up all the teams involved and we agreed on nine sizes. Originally, the logistics crew wanted as few different box sizes as possible, but the gain we made in optimisation between having eight and nine sizes was greater than the logistical effort.

What happened next?

We had to move full steam ahead because the new box sizes were supposed be used for the Christmas period. Our box supplier had to produce the new sizes on time and in sufficient quantities. Not only that, but our graphic designers were under serious pressure to create the new designs. When mid-October rolled around, the first of the newly sized boxes arrived. At the same time, we had to get through our stash of old boxes. The deadline was actually 9 November. From that point on, we only wanted to pack incoming orders using the newly sized boxes. So, we took away all the old boxes the night before and kitted out the workstations with the new formats.

What happened to the old cardboard?

We’re still using the remaining stock for large parcels. Those won’t change over to the new sizes until later on.

How did the changeover go?

We didn’t hit any major snags. The employees were also really pleased that we took their needs into account. Thanks to the new box sizes, they’re able to work more ergonomically. They don’t have to bend down as much and are able to set up the boxes much more conveniently on their worktops.

So is «Project Box Sizes» done and dusted?

The nine new sizes don’t signal the end of the line for us. We’ll regularly check if the box sizes are still a good fit for our product range. As for the algorithms themselves, we already have ideas on how to improve them even more.

What are you tackling next?

First, I want to get my end-of-term exams over with. After that, I’ll be working on a project designed to improve both workplace ergonomics and process speed. That’s all I can reveal at the moment.

News aren’t enough for me – it’s the stories behind the news that capture my interest. Curiosity is my constant companion and the reason why I spend Saturday afternoons in my favourite café, eavesdropping on city stories while planning my next travel adventure and creating new event ideas. Zen meditation can wait.

News about features in our shop, information from marketing and logistics, and much more.

Show all