Top-rated products in the Lathes category

Here's a ranking of the top rated products in this category. To give you a quick overview, we've also added some key information about the products.

1. Proxxon MICRO lathe DB 250

Creating models is a beautiful and useful hobby. Glasses, cups, pots, and columns for table dolls can be made. For railway modeling, tanks, windows, and light signs can be produced. Dolls and legs for dolls, as well as many other objects for any hobby, can be manufactured with this device. The electronic speed control allows for semi-automatic coloring at low speeds. The spindle has a bore of 10 mm for mass production of various components. The powerful motor features electronic speed regulation. The chassis is made of profiled aluminum. A centering clamp with a tension spindle is also included. Support for adjustable tools in all directions is provided.

2. Holzmann Quality rotary kit

Max total length: 56 cm. Handle: hardwood varnished. Handle length: 235 - 320 mm. Includes: 1 shaped tube (11 mm), 1 diamond-shaped cutter (6 mm), 1 round boring tool (20 mm), 1 oval turning chisel (27 mm), 1 heavy thrust tube (25 mm), 1 key tube (13 mm), and 1 wooden case with 2 locks.

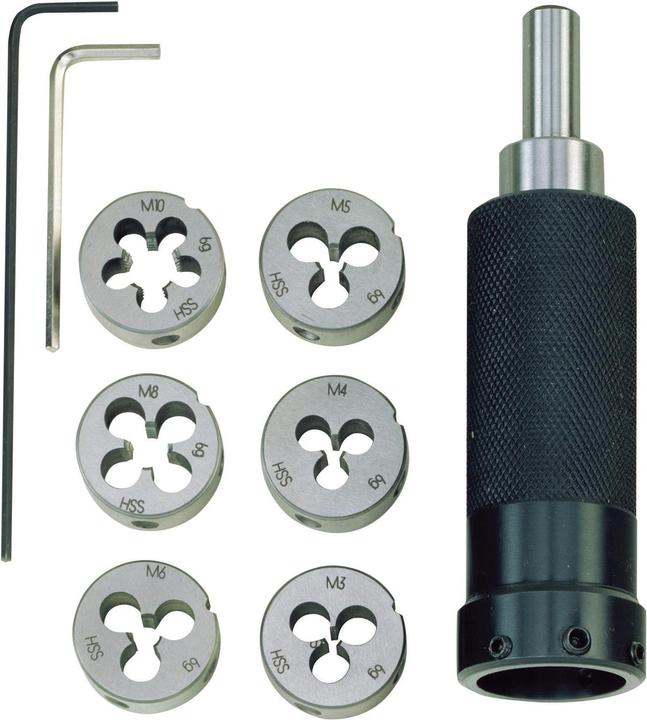

3. Proxxon Die holder

Die holder with die for external threads M 3, M 4, M 5, M 6, M 8, and M 10. With a clamping shank of Ø 10 mm for attachment in the tailstock chuck of the lathe. The holder is manually held during threading. Completely packaged in a wooden box with a sliding lid. Material: Iron.

4. Holzmann Turning professional basic set

The self-centering 4-jaw chuck DP95 provides stability to the workpiece during processing. With the 4 different jaws included in the set, a clamping range of 5 to 92 mm is covered. Suitable for Holzmann lathes.

5. Proxxon Röhm gear rim drill chuck

Chuck with tooth ring. Clamping range of 0.5 - 6.5 mm. Industrial version with high run-out accuracy (approved up to 10,000/min). Complete with pin B 10 x MK 0/short. For the tailstock of the FD 150/E.

6. Proxxon Steel holder replacement

The Proxxon steel holder set is a high-quality accessory kit for lathes, specifically designed for precise machining tasks. This set includes three steel holders, each 90 mm long, suitable for various applications such as roughing, facing, finishing, and longitudinal turning. The holders are equipped with carbide inserts that provide high wear resistance and durability. The inserts are coated at a standard 55° angle, ensuring optimal performance when machining metal. The steel holder set comes in a practical wooden box with a sliding lid, allowing for secure storage and easy access to the holders and accessories. Additionally, the package includes three spare inserts, a fastening screw, and a TX 8 key, making the use of the set even more convenient.

- Three steel holders for versatile applications: roughing, facing, finishing, and longitudinal turning

- Carbide inserts with a 55° coating for high wear resistance

- Includes three spare inserts for extended usage

- Practical wooden box with sliding lid for secure storage

- Package also includes a fastening screw and a TX 8 key.

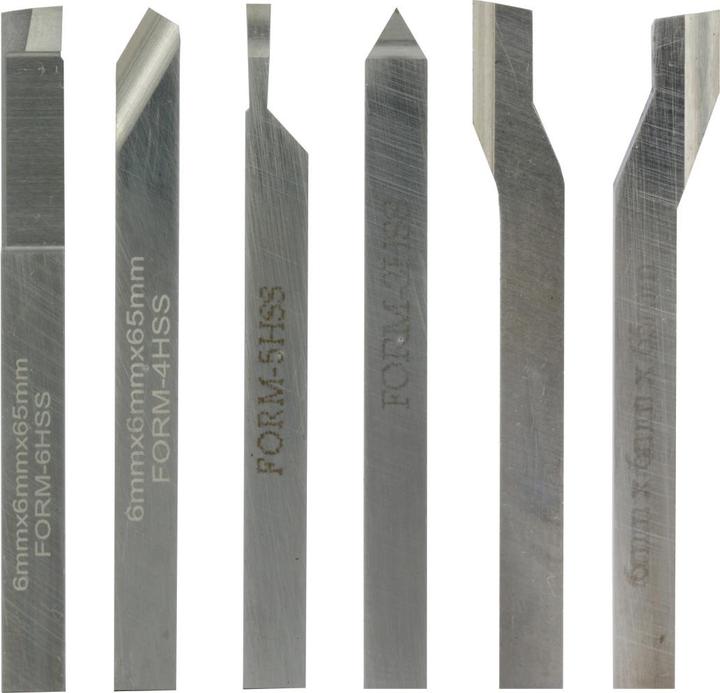

7. Proxxon Turning tool set HSS

Especially suitable for threading with the lathe. Made from high-quality HSS steel with cobalt content. Fully ground. The wooden box contains a roughing tool, a parting tool, a center drill (also for layering), as well as left and right side tools.

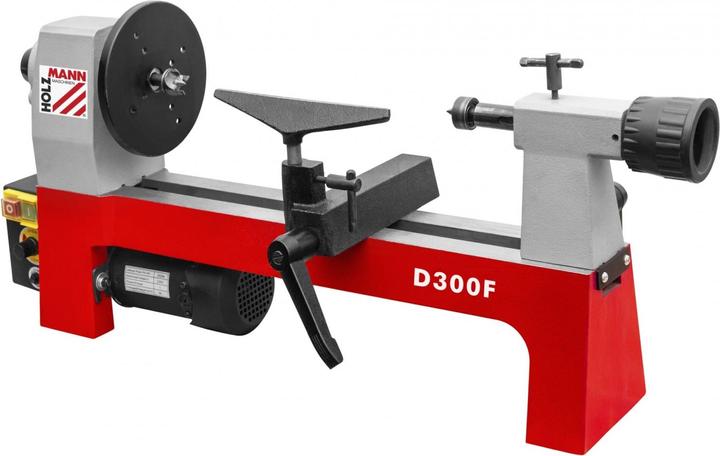

8. Holzmann Woodturning lathe

Holz Lathe Holzmann Machines D300F_230V.

9. Proxxon Three-jaw chuck

Centrically exciting. Clamping range with reversing jaws inside from 1.5 to 32 mm, outside from 12 to 65 mm. Chuck with internal thread M 16 x 1 for screwing onto the main spindle of the DB 250.

10. Proxxon Turning tool set

The Proxxon Turning Tool Set is a high-quality toolset specifically designed for use in lathes. With a total of six different turning tools made from cobalt-containing HSS steel, this set offers excellent cutting quality and durability. The tools are pre-ground and include boring tools, roughing tools, parting tools, point tools, as well as right and left side tools. This variety allows for a wide range of machining applications, from rough cuts to fine finishing work. The set is suitable for use with the Proxxon Lathe FD 150/E and comes in a practical wooden case that ensures safe storage and easy transport. The compact dimensions of the tools, measuring 6 x 6 x 60 mm, make them ideal for precise work in metal processing.

- Made from high-quality, cobalt-containing HSS steel for increased durability

- Includes various tools: boring tool, roughing tool, parting tool, point tool, and side tools

- Pre-ground for immediate readiness and precise results

- Suitable for the Proxxon Lathe FD 150/E

- Delivered in a sturdy wooden case for secure storage.