Too Many Lathes? Here's How to Choose the Right One

Discover the key factors you need to consider when selecting the perfect lathe for your needs.

Last updated 3 weeks ago. Automatically generated content.

Select options and limit the number of products

The maximum turning diameter of a lathe dictates the largest size of workpiece the machine can handle, directly impacting the type and scale of projects you can undertake. Choosing the appropriate turning diameter is crucial for ensuring efficiency and compatibility with your specific manufacturing requirements.

Popular options

201 - 400 mm

Typical price

460.– to 4100.–Handles large workpieces, suitable for industrial or heavy-duty machining.

Best for large-scale manufacturing, providing robust performance and increased productivity.

Bestseller

Max. speed refers to the highest rotational speed a lathe can achieve, measured in revolutions per minute (rpm). It is crucial for determining the efficiency and precision of machining operations, impacting the quality of the finished product.

Popular options

Up to 2000 rpm

Typical price

2000.– to 5200.–Suitable for larger workpieces and rough machining, offering slower speeds for better control.

Ideal for applications where precision is less critical, such as woodworking or metal shaping.

Bestseller

2001 - 4000 rpm

Typical price

420.– to 2000.–Provides a balanced speed for a variety of tasks, accommodating both small and medium-sized pieces.

Best for general-purpose machining, offering increased flexibility and efficiency in operations.

Bestseller

4001 - 6300 rpm

Typical price

370.– to 860.–Enables high-speed machining, suitable for smaller workpieces requiring fine detail.

Perfect for precision tasks in metalworking, resulting in smoother finishes and shorter production times.

Bestseller

The material of a lathe determines its durability, stability, and suitability for different types of projects, directly impacting the quality of the work produced. Choosing the right material ensures optimal performance, longevity, and safety, especially when working with specific types of materials like metal or wood.

Popular options (you can select more than one)

Metal

Typical price

54.– to 450.–Metal lathes are robust and can handle hard materials with precision and accuracy.

Ideal for machining metal components, they provide a stable platform for high-tolerance work, offering reliability and consistency.

Bestseller

Wood

Typical price

130.– to 830.–Wood lathes are designed for crafting and shaping softer materials, allowing for more creative flexibility.

Perfect for woodworking projects, they offer ease of use and are suited for making detailed and intricate designs.

Bestseller

The top of the range factor in lathes refers to the maximum turning diameter, determining the largest size of material the lathe can accommodate. This is crucial for ensuring that the lathe meets the specific project requirements, allowing for versatility in handling various workpiece sizes.

Popular options

Up to 500 mm

Typical price

360.– to 1600.–Suitable for small to medium-sized projects, handling workpieces with a turning diameter up to 500 mm.

Ideal for home workshops or small businesses focusing on detailed, intricate work.

Bestseller

501 - 750 mm

Typical price

2400.– to 4800.–Accommodates larger workpieces with a turning diameter between 501 mm and 750 mm.

Perfect for businesses that require flexibility in project sizes, from medium to larger components.

Bestseller

751 - 1000 mm

Typical price

270.– to 5600.–Designed for large-scale projects with workpieces having a turning diameter up to 1000 mm.

Best suited for industrial applications, allowing for extensive versatility in handling large components.

Bestseller

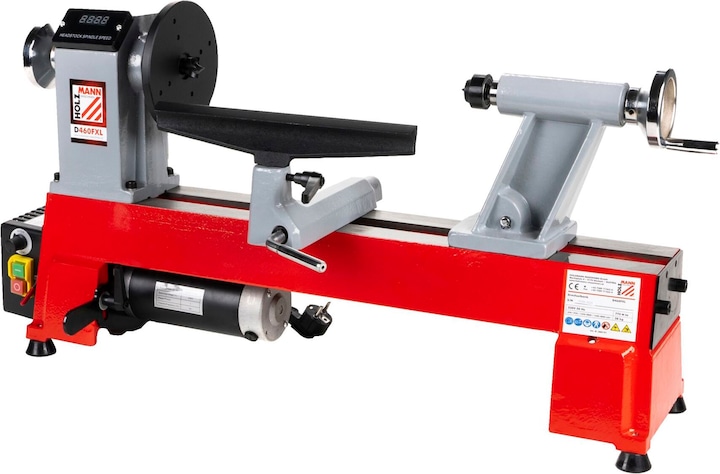

The brand factor in lathes influences customer decisions by highlighting trusted manufacturers known for reliability and precision. Brands like Proxxon, Holzmann, and Scheppach offer unique strengths, from high precision to robust construction, affecting user satisfaction and project outcomes.